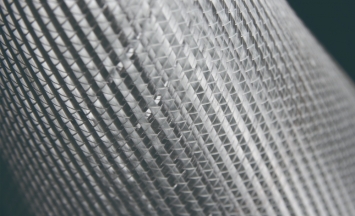

Triaxial fabrics

-

E6 -Glass stitched fabrics

Main products: E-TLX450, E-TLX750, E-TLX808, E-TLX1200, E-TLX1215, E-TLX1500; (The weight range is 450~1800g/㎡)

E6 -Glass stitched fabrics, as high-performance composite materials, have advantages of light weight, impact resistance, durability and high strength and others.The triaxial fabrics provides better axial force, aerodynamic lift and torque during the blade operation.

Test Item E-TLX1215-390 0° Tensile Strength/MPa 700-750 Modulus/GPa 30-32 -

E7 -Glass stitched fabrics

Main products: E7-TLX1200, E7-TLX1215, E7-TLX1350; (The weight range is 450~1800g/㎡)

The development of E7 high-strength and high-modulus glass fiber stitched fabrics has made it possible for high-power wind blade manufacturing, pressure vessels, pultrusion and other industries which have a large demand for high-performance glass fibers.The triaxial fabrics provides better axial force, aerodynamic lift and torque during the blade operation.With the application of E7 high modulus fabrics, the power generation costs can be lower.

Test Item E7-TLX1350-390 0° Tensile Strength/MPa 800-900 Modulus/GPa 35-37 -

E8 -Glass stitched fabrics

Main series: E8-TLX1200; (The weight range is 450~1800g/㎡)

E8 high-strength and high-modulus glass fiber stitched fabric can make the wind blades in same level lighter in weight, higher in modulus and strength, and less deformation under the same wind conditions.The triaxial fabrics provides better axial force, aerodynamic lift and torque during the blade operation. With the use of high modulus fabrics such as E8, manufacturers can make products lighter, with better performance, higher efficiency, and longer service life.

Product Inquiry

Leave us a message, we will provide you with the best solution